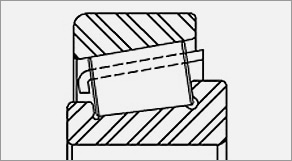

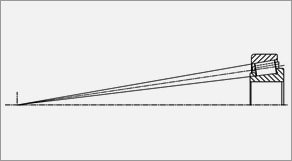

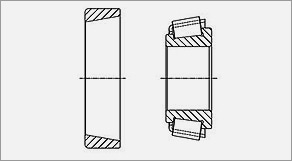

Tapered roller bearings (TRBs) utilize rolling elements that are shaped like a truncated cone (Figure 1), and are constructed so that all tapered surfaces converge at a common apex point on the bearing centerline to yield true rolling motion (Figure 2). Tapered roller bearings are generally used in lower speed, high load applications and are capable of absorbing radial and/or axial loads. The internal angles may be designed to tailor the bearing to the loading demands of a specific application. Tapered roller bearings are a separable two-piece design (cup and cone) which allows the end-use to optimize the internal clearance (and life) for each application when the bearing is mounted. PEER primarily manufactures single row (TS), sealed single row (LA), and matched set tapered roller bearings.

Tapered Roller Bearings

Tapered Roller Bearings(PDF – 4.50MB)

Features:

- High quality through hardened bearing steel

- Optimized, engineered internal geometry

- Highly consistent, reliable, and flexible manufacturing

- Globally interchangeable inch and metric designs

- Available integrated seal

Advantages:

- Improved bearing reliability and life

- Integrated seal can improve contamination exclusion to, or replace, external seals in certain applications (consult your PEER Application Engineer)

Benefits:

- Extended bearing life equals longer equipment service life

- Longer intervals between scheduled machine maintenance results in lower ownership cost

Product Offering:

- Bore Size: 15mm~200mm

- Outside Diameter: 35mm~260mm

- Ring Material: SAE 52100 ~ ISO 100Cr6 ~ GB/T GCr15

- Seal Material: Nitrile

- Precision Classes

- ISO Metric: Normal, P6X

- Inch: Class 4, Class 2

- J line Metric: Class K, Class N

- Heat Stabilization: S0, S1, S2, S3